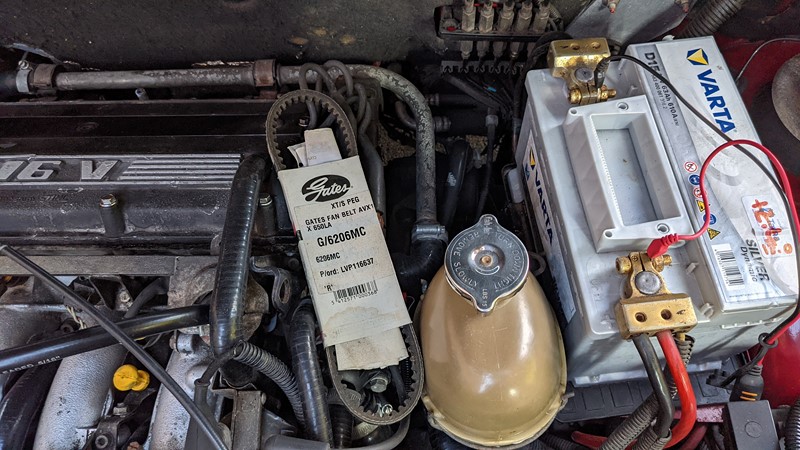

When I was washing the car for the RetroWorks show, I noticed the HP pump belt was looking sub-optimal. It didn’t seem to be slipping, but visually it wasn’t looking too helpful. So since I had a spare half hour, I figured I’d change the belt for a nice new one. Little did I know just how long it would take!

Why did the HP pump belt need to be changed?

Before I started taking the HP pump belt off, I didn’t think I was having any particular problem with it. I thought it was just a bit old. I don’t remember when I last changed the belts, probably more than ten years ago. So why change it? The last time I was up and personal with the engine bay, I noticed that the belt looked a little old and worn.

From the side of the belt, I could see the shoulders were worn. Instead of being a nice flat profile, the side of the belt had a curve warn into them, a good sign of a belt that’s getting to the end of its useable life. I’d also noticed some threads hanging out, which is never a great look. I’d also noticed that the tension adjuster was at the very maximum limit of travel, a good sign the belt has stretched or is simply the wrong length.

So why change it if it’s not broken? Well, if it does break, it’s game over. The HP pump belt takes power from the engine to turn the HP pump and supply pressure to the hydraulics. There is no suspension, no powered steering, and perhaps critically, no brakes without the belt. All significant failures on their own and complete failure would render the car undrivable. But, since I have the right belt in the garage, I might as well change it.

Getting the old HP pump belt off

Oh my, did I make the right decision to change the HP pump belt on the BX 16Valve!

It was a bit of an impulse decision to change it last night before TLBS, but I’m so glad I did, not just because of the state of the belt! Slackening off the two bolts that hold the tensioner was reasonably straightforward as the bottom pivot bolt was already loose. Getting the belt out was not so straightforward. One of the coolant pipes on the back of the engine was secured, but a hose clamp was very much touching the HP pump pulley, making the belt impossible to get off.

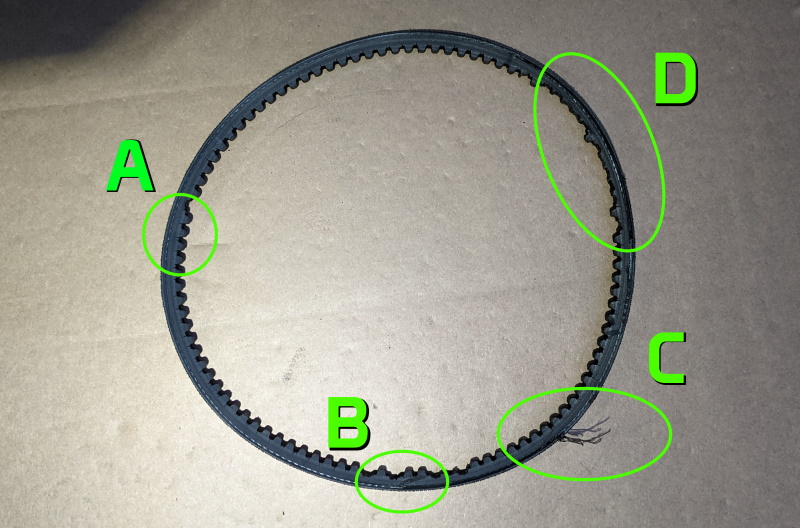

Eventually, I opted to take the camshaft pulley off to access the hose clamp as I simply couldn’t reach from behind. Over thirty minutes later, I finally had the old belt off, and what a scary sight it was to see. A quick synopsis of what’s in the picture above includes;

- A – Blocks/teeth tearing away from the belt. Its not clear in the picture but some of those cracks are real deep

- B – Gauging of the side wall, on top of the already warn sides, this isn’t going to help performance

- C – Some of the sidewall wear has resulted in the reinforcement braiding escaping

- D – And finally there is a couple of teeth missing.

The HP pump has been a little noisy for a while, but at 30 years old and still on its original HP pump, I figured this was normal but was it just noise from a failing HP pump belt?

Failing to get the new HP pump belt back on

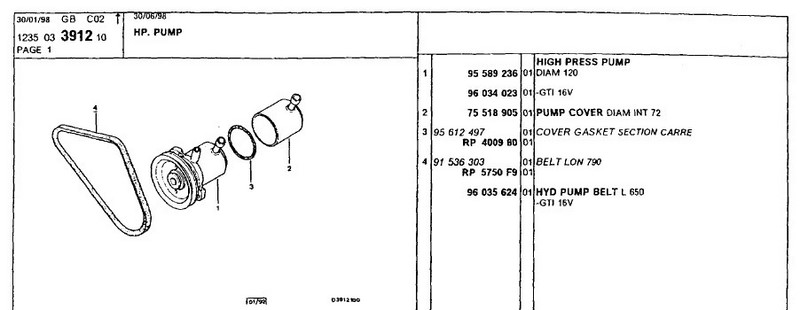

According to the Citroen parts catalogue on Catcar.info the BX 16 Valve, shown as GTI 16V below, should have a 650mm long belt. And I have a 650mm Gates belt in stock, which was intended for a BX 16Valve. Well, after forty-five minutes of battling, I have no idea how anyone can get a 650mm belt on. It’s simply not possible, not with my hand strength anyway.

In the end, I used a 674mm HP pump belt (can it really be 674? surely it’s 675mm). Only 25mm longer but a big difference in the fitting. I still had to take the tensioner completely off, slot it onto the belt, put the adjustment bolt in, then put a lot of force in to line up the pivot bolt. I hate whoever designed this system. Actually, that’s not fair. It’s not designed. It’s bodged together.

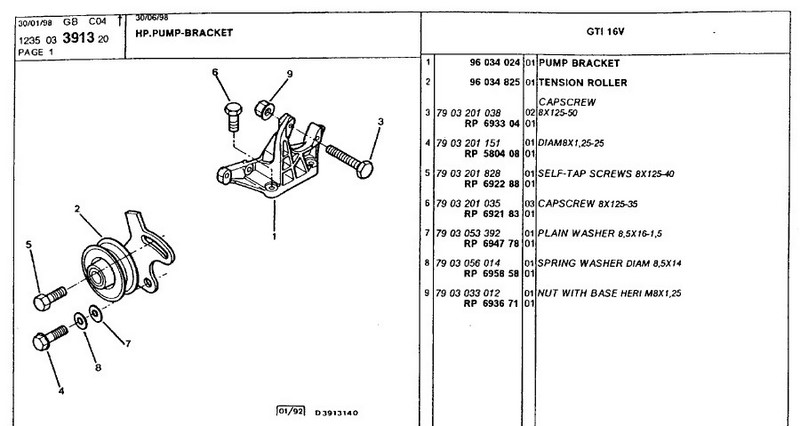

I noticed that the bracket that holds the HP pump to the gearbox was missing a long bolt. The top bolt, marked number 3 in the picture above, was present, but the lower bolt, nowhere to be seen. This is because there’s a lot of force in the HP pump belt, especially when the accumulator kicks in and out. Certainly enough force to cause the pump to bounce about.

Finally getting a new belt on

Two hours after I started, many cuts and bruises to the hands and a range of swear words were tested, and I FINALLY have a new belt installed and tensioned up. The HP pump belt tensioner is now only halfway along its adjustment travel, which makes me much happier. Knowing that the belt isn’t entirely chewed up gives me a little more confidence in the car too.

But perhaps the most noticeable change, the hydraulic drive system has become quiet. I wouldn’t have said it was especially noisy to begin with, but it was undoubtedly rattly. In fact, the engine note change when the accumulator kicks in and out isn’t anywhere near as obvious. I don’t want to jinx it just yet, but it also seems that the rattle I hear on startup has gone. Was this being caused by the unsecured HP pump after all?

A maintenance job well done, I think!

M

PREV – Citroen BX – Cooling Fan Replacement

NEXT – Show – The Late Brake Show On Tour

Back to Citroen Articles

Back to Automotive articles