Having recently replaced the ailing 30-year-old wiper mechanism on the Citroen BX, I thought I’d see just what went wrong. After a quick teardown, the problem is pretty obvious and probably easy to fix. Let’s have a look.

Replacing the wiper motor

I’ve recently released the YouTube video below, showing just how much play was in the 30-year-old wiper mechanism. In the video, it’s clear that there is wear in the central pivot/shaft causing the wiper to flop around. The close up shows just how the pivot is oscillating in an oval path.

I want to understand if there is an underlying problem with the design, other than simply age. I also want to know if it can be readily fixed. The only way to do this is to teardown the wiper motor assembly.

Understanding the Mechanism

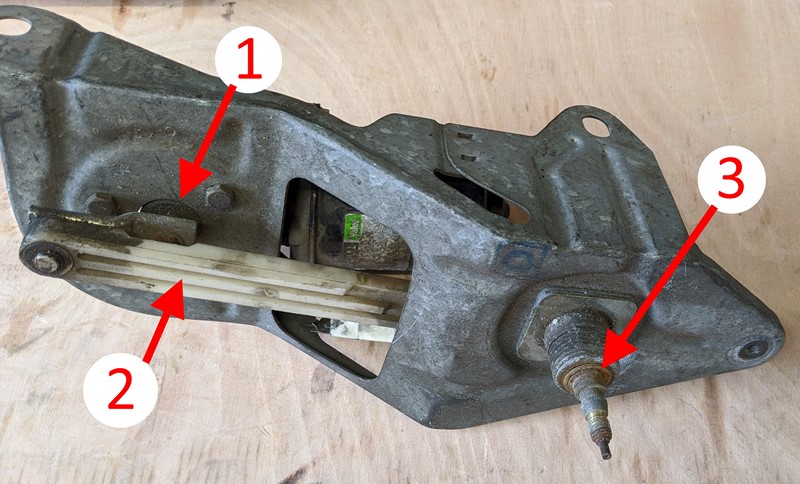

The wiper mechanism on the Citroen BX is a very simple affair, in part because it only drives a single wiper motor. It has four main components. Firstly the motor (1) rotates in one direction but has some indexing so that it has a known ‘stop’ position. The linkage (2) turns this rotary motion into a ‘push/pull’ motion. This in turn forces the output shaft (3) to rotate one way then the other. All this is connected to the metal frame.

Teardown – Wiper Motor

Before I took the mechanism off the car, my suspicion was that the motor might be the cause of the issue. But that was ill-placed suspicion. There is no play in the motor output shaft at all. Before taking the mechanism apart, I tested the motors stall current by jamming the linkages with a screwdriver and applying power. What I discovered was two things, there is no safety stall detection in the motor, and this little motor is way stronger than I am.

Teardown – Linkages

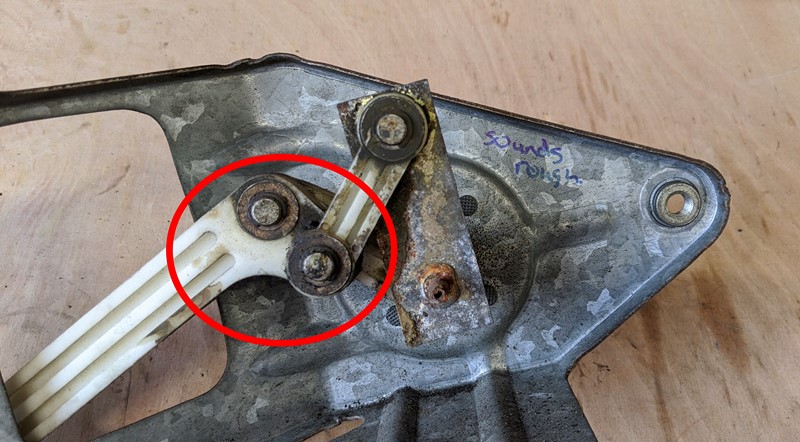

While the pivots on the linkages are rather dirty and dry, they didn’t seem to have any play. Certainly not enough to cause the oval pattern the base of the wiper arm was following. For reference, the linkage highlighted in red can be flipped over to make a left-hand drive mechanism into a right-hand drive mechanism. At least I’m pretty sure it’s this bit that gets flipped.

You might also notice the notes on the metal frame ‘Sounds Rough’. I normally put notes like this on salvaged parts before I put them into storage. I thought this car had the original mechanism to the car, but this makes me think perhaps I’ve changed it at some point, perhaps because it was worn out?

Teardown – Wiper mechanism pivot

Before pulling the mechanism apart, I noticed a gap around the boss through which the output shaft passes. In fact, the gap is notable and it is on either side of the shaft and not all the way around. This would be consistent with an oval pattern, but the gap is nowhere near enough to create the amount of play previously seen.

But with the output shaft removed, the cause of the play is immediately apparent. The circular hole at the bottom on the output shaft boss clearly hasn’t been round for quite some time. In fact, it looks like the removed material has been sprayed all over the metal frame. I can only imagine a lot of water has got in here. The boss is a separate part of the frame and is softer cast metal, held in place with the four ‘rivets’ shown.

The output shaft is held into the output shaft boss with circlips in the grooves on either end. The raised sections of the shaft, highlighted, then act as bearing surfaces. Before the picture above was taken, the shaft was cleaned of all the corrosion that had built up. I suspect it is corrosion which has caused the wear in the soft metal of the output shaft boss, and allow the hole to become oval in nature.

Making a repair?

Now the wiper mechanism teardown is complete, there are a couple of options for making a repair to the boss. I could make a whole new boss from scratch. Weld up either end and drill the hole round again. Or perhaps open up the hole to make it round again and add a sleeve to bring the size back to match the output shaft. Perhaps a sleeve made from phosphor bronze, although that may just wear out the shaft.

In fact, as I sit here I can think of many more solutions. But I have a lathe so I should probably start with freeing the boss from the metal frame. Then I’ll need a new article on which way I make the repair.

M