When using the Symptom Driven Diagnostic tool (SDD) you need to maintain a constant battery voltage. With the ignition on, the power draw of the car is higher than the battery can supply to support this voltage. Let’s look at why we need to sustain a constant voltage and why a battery support unit can be the best solution.

Why do we need to achieve a minimum voltage?

In a previous article, we looked at how CANbus operates and how the hardware determines pulses between two reference voltages in order to decode bus messages. When vehicle voltage drops low, the difference between a high pulse and a low pulse becomes harder to determine and can lead to errors. To avoid this most modules have a voltage below which they will shut off.

Quiescent current draw.

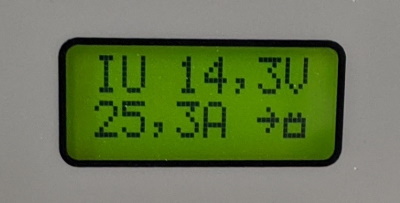

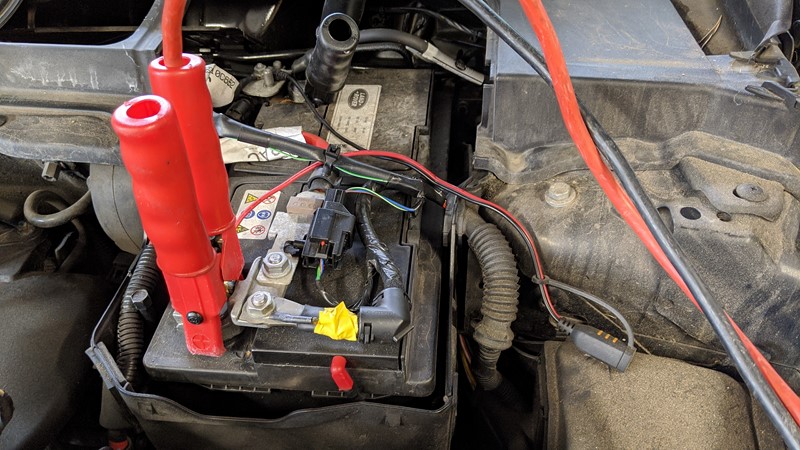

While connecting to a vehicle with SDD you’ll need to leave the ignition turned on so that all the electrical modules are powered. This means that there will be a current draw, a slow draining of the power stored in the battery leading to voltage sag. In the case of my own Freelander2, I usually see a quiescent draw of around 25Amps when the battery is fully charged. It is the original 7-year-old battery.

The standard, non-stop-start Freelander 2 battery is 75Ah. So, in theory, you can draw 20A for 3.75 hours. Seems like a long time, and it is. Only the calculation is not that simple. For a start, the 75Ah rating is based on 12v stating potential and is not an indication of voltage over time.

Then there is degradation over time of the lead-acid battery which significantly reduces this capacity. This is the ultimate reason why car batteries need to be replaced.

The reality is you may only manage to keep the battery above the required voltage for around 15 minutes! That’s what I get on my car and is common on other cars I’ve worked on

What voltage to achieve?

Dependant on where and who vehicle ECUs are manufactured for, there can be quite a range of operating voltages. In most cases, the absolute minimum is ~9.7V and maximum is 16V. Manufacturers also sometimes have a minimum engine crank voltage, typically between 11.3V and 11.7V.

A nominal voltage for a car with a healthy battery and engine NOT running is usually between 12.3V and 12.8V and this is the more critical for SDD as most operations are carried out with engine OFF and ignition ON.

SDD will regularly give a pop-up expecting a minimum of 12.5V. It won’t start many operations without a battery voltage over this level. Your battery is rated at 12V so it’s going to need to be in perfect condition and fully charged if you don’t have something to support the load on the battery.

Battery Charger Vs Constant Voltage Supply Vs Battery Support Unit

There are often misunderstandings as to why you need a battery support unit when using SDD. Typically is you’ve just turned off the engine, SDD sees a sufficiently high voltage to start a routine. It does not check again. This often means people using SDD at home do get away with making changes without battery support. If you’re quick you may never run into problems.

However, I am strongly in favour of looking after my car battery, not excessively depleting it and not risking having to buy replacement ECUs. All of my cars have CTEK connections for trickle charging. If they are left for longer periods, I will usually take the battery out of a project car. This year I finally replaced the battery in the BX and it was 15 years old going by the receipt. No like time warranty, unfortunately!

Battery Charger

A decent battery charger is a little better than nothing, though it is likely only buying you time. Modern chargers such as the CTEK or NOCO are intelligent. They will switch between cycles of constant voltage and current to maintain a battery in good health. But these typically are around the 5A supply mark and don’t have enough power to overcome the 20A quiescent current draw.

For a long time, I used a RING RCB320 workshop charger. This is a crude and not intelligent charger. It’s only one diode away from simply plugging the car into the mains. It has a nominal 3A trickle charge but could also manage a 20A fast charge. The simple coil inverter design means it is very inefficient at converting AC to DC, producing a lot of waste heat. This heat breaks down the coil insulation. In my case, it “let go” in spectacular and smokey fashion in the middle of flashing a module!

Traditional Power Supply

Another favourite for many years was a Wayne Kerr branded bench power supply. With a capacity of more than 60 Amps, it’s enough to power the car even without a battery. In the early 00’s they where the go-to bench power supply in automotive and you can find them for £200.

A bench power supply is limited in functionality. They can run in constant current or constant voltage but will not automatically switch the way a modern battery charger can. You’ll struggle to find one that isn’t at least 20 years old which means a lot of electrical gremlins. Common issues are the failing of the RIFA capacitors on the high side and wandering voltage sensing. A one-off repair by the original designer/supplier is a further £600!

There are modern equivalents but they too are around £600 starting price and around £1200 for a decent brand. My personal favourite is the TDK Lambda Genesys range.

Battery Support Unit

A battery support unit has a high current capacity and intelligence. These are what are used in dealerships and there is a huge range of OEM and aftermarket variants. Support capacity starts at 50A which is the minimum you’d want for a Freelander 2. Battery support units go to 120A and beyond for more recent (ECU filled) vehicles. Below are my favourites.

‘The Black Brick’ – BSU2-50B

The BSU2-50B from Traction, or better known as ‘The Black Brick’ was the standard Battery Support Unit for JLR for many years. It’s still pretty common on showroom floors but at 50A its a little underpowered for modern cars. It currently retails at £650.00

Fronius Acctiva

The Fronius Acctiva 70A ‘Battery Conditioner’ has become something of a common sight around dealers and garages both OEM and independent. At 70A it has the power for more modern cars, and its lightweight and easy to use. It also has incredibly long cables (battery and mains) which usually means no additional extension is needed. This is the battery support unit I’ve used the most in my automotive career. At £1400 it’s more than twice the price of the black brick.

VAS

Volkswagen Group Service has a number of different battery support units, under the ‘VAS’ name. These are sourced from a range of companies. The VAS 5903 is made by Akkuteam which is a well-established brand in the field of battery charging, even though it looks identical to the Fronius! As I write there is a VAS 5903 on eBay for £1600.

Gysflash

The Gysflash brand is a reasonably new brand to me. They seem to make units for a number of big-name tools suppliers such as SIP. The units come in a range of output powers, and wall or floor standing. Gysflash battery supply units are readily available and cheap. Perhaps most importantly for a busy garage, they come with replaceable cables. The GYSFLASH 100.12, with a 100A capacity, is currently available for only £615. This is currently my go-to suggestion for anyone asking which to buy, but at this point, I currently have no personal experience with them.

So what do I use?

Well, I use a range of these options! At home, I have a black brick and professionally I use the rest in different garages around the world. If I just want to read data quickly, I may not use any battery support. The risk is a flat battery which is more of an annoyance than anything. From experience, if I want to write data to a non-critical ECU then I may do it with the engine running.

As a rule, at home, I always write critical data such as a CCF with a Battery Support Unit. I’ve been bitten with spectacular failures at work without a Battery Support Unit. Losing days, and hair, recovering vehicles with the correct toolchain and support. I’m not willing to risk my car and my sanity at home.

M