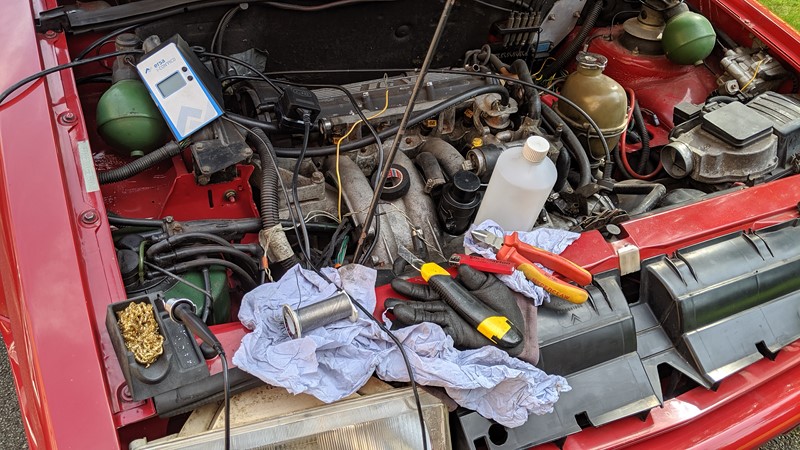

After the breakdown in June 2019, it was time to bite the bullet and finally replace the sensor harness from the bulkhead into the engine. The first job was to drag the old wiring harness out.

Un-bodging

While taking the harness out, I noticed a couple of concerns with the engine management loom. There was an odd routing to the throttle position sensor, and a previously repaired connection to an injector had discoloured, which is never a good sign.

The ‘repair’ I made when throwing the Mi16 engine onto the car in 2008 had been done by twisting the wires. It is not the prettiest of connections with no crimp or solder, just a bit of tape. Fixing this connection took slightly more effort to resolve than I had planned.

Harness Replication

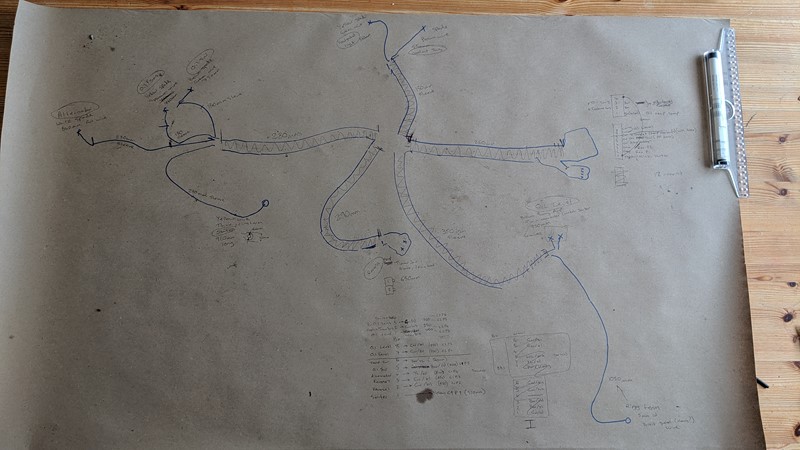

So with the sensor harness off the car, the easiest way to replicate it with the correct lengths was to trace it. So bring out the BIG paper!

Some tracing, then removal of the conduit and measurement of the individual wires, gives us a complete map of this harness section. And the start of something new.

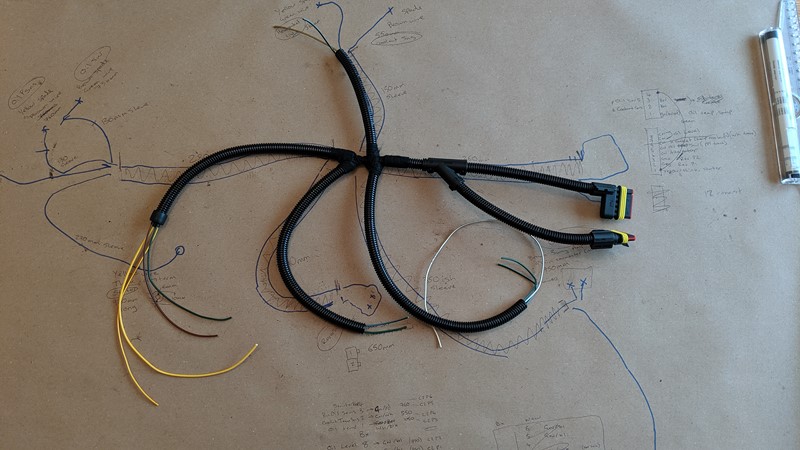

Then, a few hours of routing wires, joining trunking, cutting, terminating, splicing, and a replacement harness starts to form. Most parts came from PoleVolt, with a few Citroen-specific connectors ordered directly from Tyco.

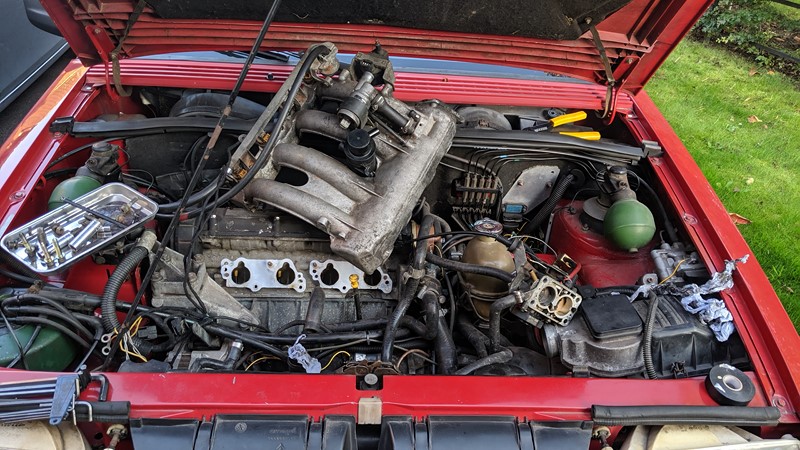

Reinstalling the new harness

The harness was correct the first time, but getting back onto the car was less than straightforward. Ultimately the intake manifold had to come off to get to the oil sensors (pressure and temp). But with it altogether, the car started, and more than a few issues were resolved.

M

UPDATE 17/07/2020

Six months, one MOT, and nearly 1000 miles later, everything is working as it should. After I resolved the air leak I created while I had the intake off to install the harness, the car has been working the best it ever did! So, where do I stop now? Should I be replacing the whole cabin side loom?

Maybe I’ll just enjoy it for a while!

M

Amazon Affiliate Links – Things used in this article

BXProject is using Amazon Affiliate Links. It’s a quick way to show you what I have used in this article.

“As an Amazon Associate, I [may] earn from qualifying purchases.”

Since January 2024, Amazon has blocked embedding images, but I think the links are still valuable.