Way back at the start of March I wrote about how one of the crank rod journals was measuring undersize. Well, it created quite a quandary, with a plethora of options for repair or replacement. In fact, it’s a topic that was so far outside my knowledge, I’ve had to do an awful lot of learning. I’ll try to share that learning journey with you, though fair warning, this is a boring topic.

Dissection of a crankshaft

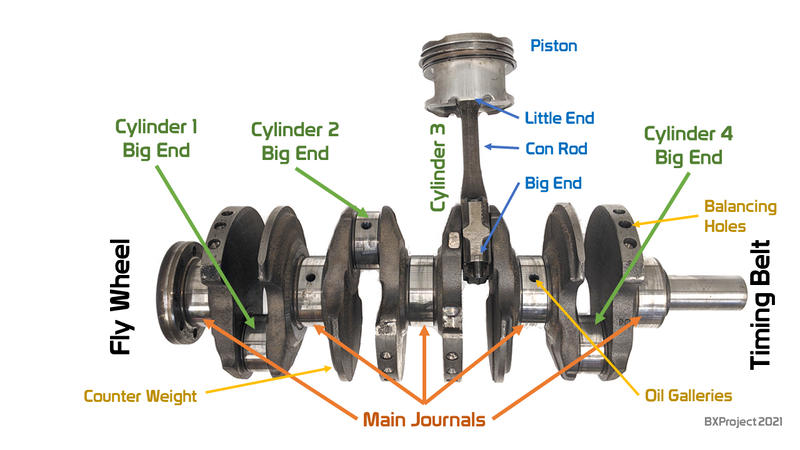

There are quite a few uncommon terms used when discussing the bottom end of an engine so I think it wise to lay those terms out. I can’t say I understand all the terms, and I may get some wrong, but if I show my understanding, we can at least be on the same page.

I’ve tried to label some of the key parts, but what I seem to have done is make an overly complicated infographic. Sorry. Let’s try to break down some of this confusion.

- Flywheel and Timing Belt – To give some orientation the flywheel (gearbox/output) and timing belt ends of the crank are labeled. It’s the normal convention to number cylinders from the flywheel end of the crank.

- Piston assembly

- Piston – This is the bit that goes up and down in the cylinder. It is what sees the full force of explosions in the engine, one tuff little cookie

- Conrod – This is the connection (hence the “con”) between the piston and the crank

- Little end – As it sounds, this is the smaller end of the conrod and the connection to the piston.

- Big end – This is the big end of the conrod and the connection to the crank.

- Main Journals – This is where the crank sits in the lower engine casting.

- Big Ends – Each cylinder’s big ends are labeled.

- Oil galleries – In a perfect world the journals sit on a thin layer of oil and not directly on the bearing surfaces

- Counterweight – Help to balance out the explosions from each cylinder, we’ll come back to this

The troublesome crank

After the bottom end teardown, I took the parts for cleaning at my new favorite engine place, EMS. While there they measured out the original crank and found the cylinder 2 big end was undersize. The target diameter for the big end is 50.00mm, and a minimum standard measurement of 49.98mm. Anything under this is considered undersize. The number 2 big end on this crank measures 49.89mm. That’s 0.1mm under or the width of a thick human hair.

While 0.1mm sounds pretty insignificant, in engine building terms, that’s a lot of play. Remember this bearing surface connects the explosion in the cylinder to the crank, and ultimately the wheels. Every time the air-fuel mixture ignites in the second cylinder, the piston is going to accelerate towards the crank. And that gap will mean instead of the con rod pushing the crank, it’s going to hit it. Beyond the initial loss in power, over time that will flatten the bearings and left long enough, cause significant damage.

Fixing the crank, to grind or not to grind

There are a couple of solutions to resolving this single undersize big end. Between the metal of the conrod and the metal of the crank sits a thin, soft piece of metal called a bearing. It’s made of two halves, called shells. The manufacturer Mahle offers a great insight into the basics of journal bearings. Typically these bearings are a couple of mm thick, and also come as oversized sets.

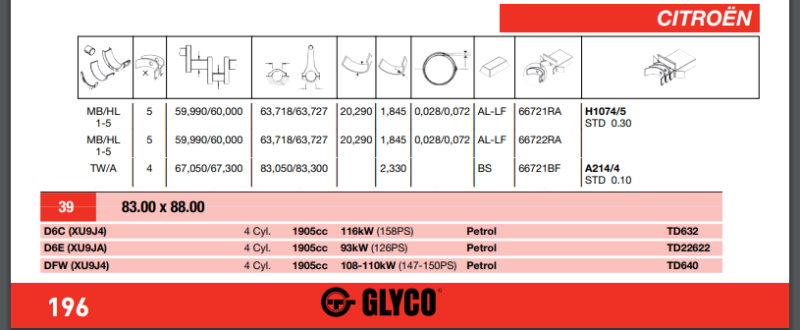

This means I can buy a set of bearings that are 0.3mm thicker, taking up some of the missing material on the journal of cylinder 2. To get the journal to be an even 49.7mm all around, I need to have the crank ground. This is a common but specialized process that involves taking metal off the crank with a high level of precision. This then raises the question, should I grind one journal or all the journals?

Crank grinding is usually priced per journal, so I could just have the one wayward journal corrected for the lowest cost. But then I need two sets of big end bearings, one standard set, and one oversize set. And if I only resize one journal, it’s likely to cause the next owner some confusion if it needs pulling apart again. The correct thing to do would be to regrind all journals.

Old crank or new crank?

Having asked this question on but the BXClub Facebook group, and on my Twitter feed, a few people suggested another option. Change the crank. More specifically, change to a DW8/DW10 crankshaft. These are found in diesel engines and are, for the largest part, the same dimensions as an XU crank found in the Citroen BX 16Valve. They come with some added benefits too. First off they are very common, so easy to find, and cheap. They are forged rather than cast, theoretically making them stronger. And perhaps most interestingly, they are reportedly 4kg lighting!

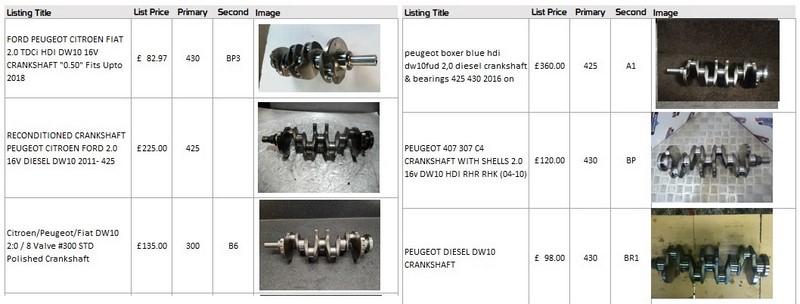

I started looking at alternative XU-derived cranks and quickly noticed a problem. There are literally hundreds of variants. The crank type is stamped into the metal so it’s easy to determine which is which, but there is a huge range of them. I was given some pointers on what to look for and hit eBay to do some research. I needed to find an early DW10 crank, likely from an early 2.0litre HDi.

Comparing the DW10 and XU9J4 crank

Buying car parts on eBay can be something of a lottery. Beyond not knowing if an ordered part would actually arrive, I couldn’t guarantee it would be any better. What if I ordered a DW10 crank and it too needed grinding? In the end, I took a low-cost gamble and ordered a crankshaft listed as “Citroen Peugeot 2.0 HDi RHR/RHJ”. That was the entire listing. Not mileage, only the one picture. What could possibly go wrong?

Well, it arrived by courier in less than 48 hours and incredibly well wrapped. A good start at least. The crank itself looks oily and used, but it very good condition. But then so did the original XU9J4 crank the engine came with! This is a ‘430’ crank which seems to be the most commonly recommended for the Mi16 engine. Its secondary stamping is ‘8H’ which despite all the research I did, I’d not come across before.

The difference in crankshaft weight

Comparing side by side, the reason for the difference in weight is immediately apparent. While the XU9J4 crank has a counterweight on either side of each big end, 8 in total, the DW10 only has 4 counterweights. Could this really represent a 4kg saving as had been claimed? It seemed impossible, but there was only one way to tell.

Borrowing the bathroom scales while the other half was out of the house, the comparative weight is a touch less than suggested. A difference of 800grams is a long way off the 4kg claim, but as a proportion of the overall weight, it represents a 5% weight reduction. Reducing the weight of the crank typically increases engine pickup, allowing the system to increase rotational speed quicker. As I really like the way the Mi16 engine spins up, this made me a little nervous. I don’t want to change the feel of the car away from the standard. But 800grams shouldn’t make too much difference.

Is the new crankshaft fit for purpose?

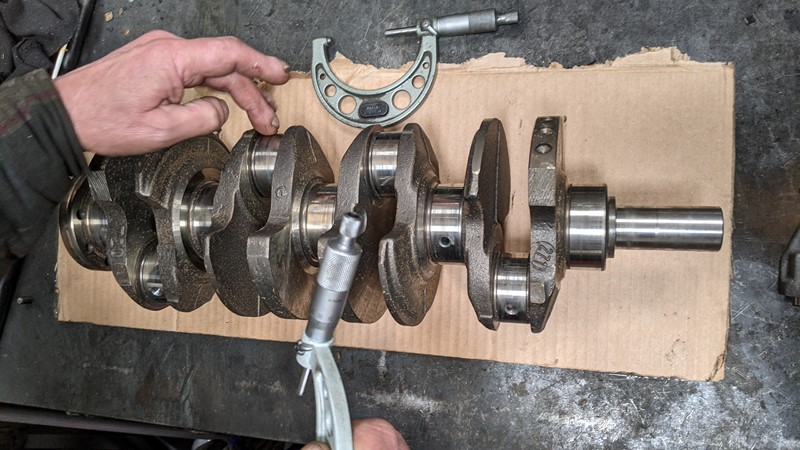

This new crank being something of an unknown in terms of condition, it might need just as much grinding as the XU9J4 crank I already have. There’s only one way to find out, measurement, bring on the micrometers! Each journal was measured in the flat and vertical planes, and while I was at it, I remeasured the old crank. And the results?

The result of all this measurement, this is a mighty fine crank. In fact, it’s not worn a bit, practically as fresh as the day it left the factory. So good that I didn’t believe the final values and the reason I went ahead and remeasured the XU9J4 crank. Reassuringly my measurements of the old crank matched that of the machine shop, so I guess I might remember how to take the measurements after all.

The final verdict on the crankshaft

I’m still a little nervous about the effect of using a DW10 crank in the XU-derived D6C engine. Not so much if it will work, but how it will perform. If the XPO restoration is going to be, at worst, cost neutral, then I’m going to have to go with this significantly cheaper alternative to getting a crank back into the engine. And with the crank being fully in spec, I can use standard bearings on every journal, which simplifies the build.

I guess I just need to get on with it now!

M

NEXT – XPO – Building the Bottom End

PREV – G-SEG Engine History

Back to Citroen articles

Back to Automotive articles

I’d call that a result. I understand your concern but as it’s a tried and proven mod, and the new crank is just about perfect, then I know what I would do. If there is much of a difference in spooling up I think you would get used to it very quickly, similar to having the flywheel lightened.

I think I agree. The replacement crank is a good £200 saved against regrinding a crank. And I expect a 5% weight change in the crank is going to have a pretty menial effect on the way the car feels on the road. M