Before I set about tearing down the engine, I want to see if I can track down where the horses are getting out. The last rolling road the engine underwent suggested just 140bhp remained of the original 166bhp. So I’m looking to find the missing 20 odd BHP with some cylinder head leak testing.

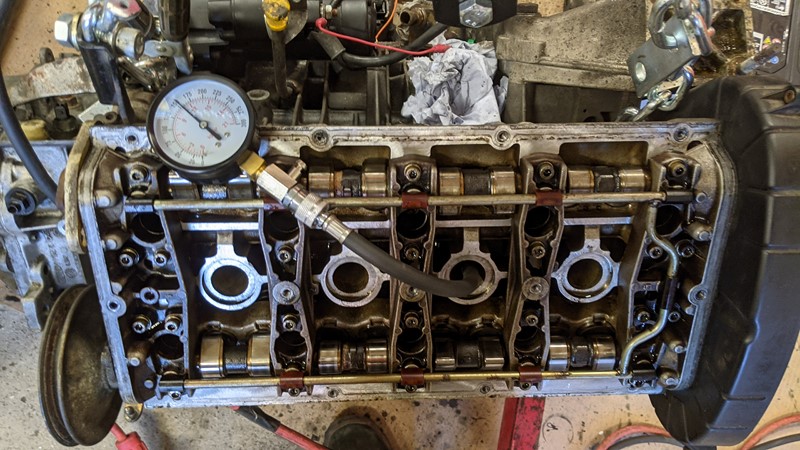

Engine Compression Test

First up is the classic cylinder compression test. A simple enough, time-honoured process, involves putting a pressure gauge on a cylinder and spinning it over. The first step is to remove ALL spark plugs, then take the rocker cover off. Then screw the gauge into the first cylinder and spin the engine over 5 or so times. Now, here’s the thing. I know it should be done using the starter motor and a well-charged battery, but I tried doing it by hand. I’d already stripped the box off, so figured I’d give it a go by turning the crank with a 1/2″ ratchet. Well, it didn’t work, reading about 1/5th of the pressure it should on what was a running engine!

Once the flywheel, gearbox and starter motor where reattached, and the engine turned over, I could see far more realistic values. I won’t spoil the result just yet, but it was immediately clear one cylinder was very unhappy. I’m using a US Pro 5323 Cylinder Pressure Test gauge. It’s cheap (£15) so I doubt it’s well-calibrated, but it will give me a relative indicator between each cylinder. Now at this point, I could wet the cylinders to find if leaks are past the cylinder rings or out of the valve, but I’ve got a different plan.

Pressure Leak Test

A simple pressure test of each cylinder will show me just where that missing brake horsepower is getting out of. For this bit of diagnostic testing, I’ve bought a ‘Katsu’ branded Cylinder Pressure Test Set from AIM TOOLS. Again, this is a cheap tool intended to be an indicator. It’s also a tool I can use on some other projects, so shouldn’t be a single-use tool. I’ve bought a few tools advertised as ‘Katsu’ brand in the past, they never say Katsu on them, this one says ‘Orazio’. It does come with some decent instructions, which is handy as its not the most intuitive tool.

The testing here is in two parts.

The first part is to see just how much pressure each cylinder is leaking. The right-hand gauge gives a ‘percentage loss’. It’s not a precision piece of equipment so some leakage is expected throughout the system. We’re also only pressurising to 20PSI and a top dead centre (TDC). I’m using a stick in the spark plug hole to watch for TDC as I rotate the crank.

The second part of the test, assuming a cylinder has a leak, is to try and see where it is getting out. There are three obvious places for air to get out. Inlet valves, exhaust valves and past the rings into the crank and back out the dipstick tube. So with a cylinder pressurised, I apply a bit of Rocol Leak Detector Spray to each set of valves. Repeating for each cylinder in turn. And the results speak for themselves.

Cylinder 3 is leaking air through both the inlet and exhaust valves in a very big way. This matched the original cylinder pressure test, which is always positive. All of the inlet valves are losing a little air, suggesting the valves need lapping. However, the cylinder 3 valves are going to need more than spinning with a stick.

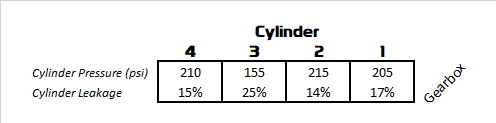

Test Results

So how do the indicative numbers line up?

Well, the cylinder pressure test results for cylinders 1,2 and 4 all match up. In fact, they are very close, the difference is probably more in my wonky eye than in the cylinder its self. I can’t find any reference values for this Mi16 engine so I don’t know if they are good or bad. My back of a fag packet calculation suggests around 14bar/203psi. That suggests these numbers aren’t unreasonable if the (cheap) gauge is reading a little high.

The cylinder leakage test supports the pressure test really well. It’s always nice when two test tools agree with each other. Unless they’re both out by the same amount of course! In this case, 25% leakage on cylinder 3 stacks up with the bubbles out of the intake and exhaust valve. So we know where the pressure is getting out but is the engine tired or are there underlying problems?

Overall condition

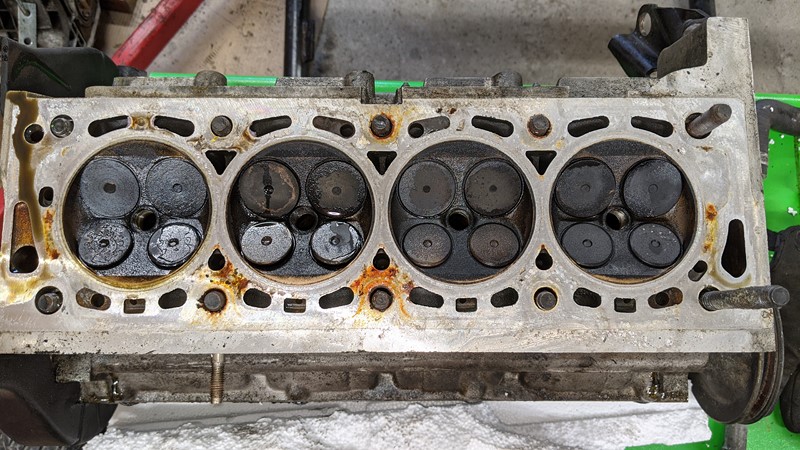

The only way to know what condition the surfaces are in is to pull the head off and have a look. Undoing the bolts in the reverse order of tightening pattern in some hope of avoiding an aluminium banana. The head bolts were incredibly tight. I had to use a 4′ breaker bar and a full cup of courage to get them to start moving. That said, they where ALL tight, which is positive.

So good and bad parts on the inspection of the head surfaces. The engine came with a separate pack of ‘service history’ from the donor car. This is why you should always buy cars from paperwork geeks. I can’t find any record in the history of the head having been taken off, but it has clearly been apart at some point. There is also some clear coolant bleed through layers of the gasket causing the rust patches. There was no milk in the oil or the breather system, so I don’t think this has caused any problems.

What is very clear on close inspection, is that all the valves in cylinder 3 are not Citroen/Peugeot originals. The material is clearly different from factory valves. The valve centres on cylinder 3 have different depression shapes than the rest. And the exhaust valves are missing the chamfers that the originals have. I guess it snapped a belt at some point, but how hard?

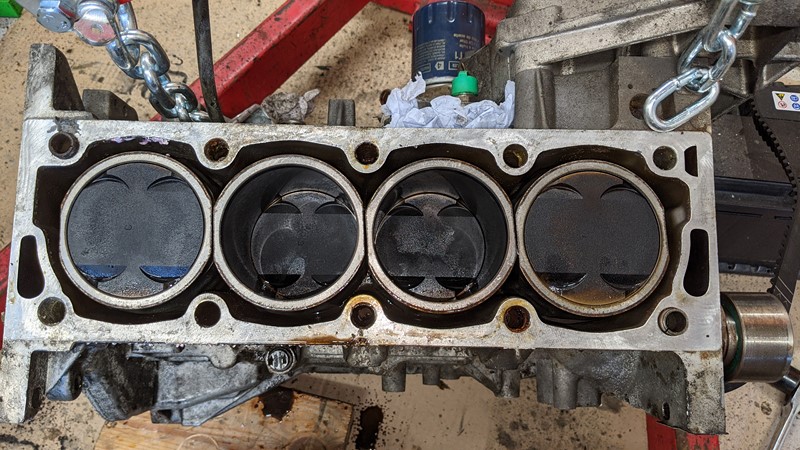

Well, I’m happy to say that if the belt did let do in the past, there is no evidence of any valve to cylinder impact. In fact, after a quick clean up, the only marks on the piston heads are those that were put there 30 years ago in France. It’s all looking pretty tidy down here, but the cylinders are super smooth. My understanding is that this glazing isn’t good for piston rings so probably needs looking at.

Cylinder head rebuilt

Despite the less than ideal leak test results on cylinder 3, this head isn’t in too bad of a condition. I guess I need to strip and rebuild the head. The first thing will be to whip out the bad valve(s) in Cylinder 3 and see if they are simply poorly fitting or in fact, bent. The strip down I can do my self, but grinding the valves and decking the head I’ll outsource. Unfortunately, my usual place is a good hour drive away. Hardly an essential journey, nor is it on the way to anywhere I’d normally journey to. I wonder if anyone does cylinder head work by post?

M

NEXT – Cylinder Head Overhaul

PREV – Mi16 Engine Strip

Back to Citroen articles

Back to Automotive articles