Once the MI16 engine was out and the cleaning started, some of the ancillaries could be removed. I’m quite amazed at what I found during the engine strip. While the engine has supposedly only been looked after by professional garages, it doesn’t show!

How much sealant is enough?

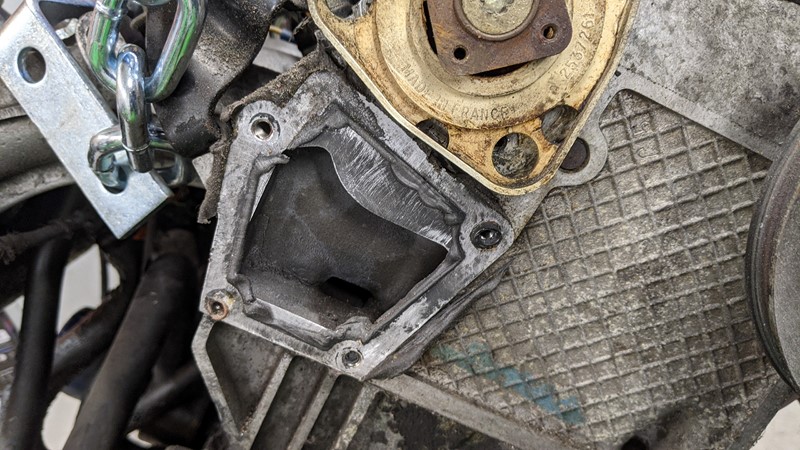

Something that was obvious through the engine strip, was the love of sealant. I’m not anti sealant, in fact, you can’t get away from it. But whoever built up this engine seemed to use the moto ‘Don’t use enough sealant, use it all!‘

This is just one example of many. Huge amounts of sealant which will likely break off and enter the fluid stream. It make not seem like a big problem in the engine coolant, until a big piece block ups a coolant gallery. It’s also a pointer to the poor level of maintenance on the engine.

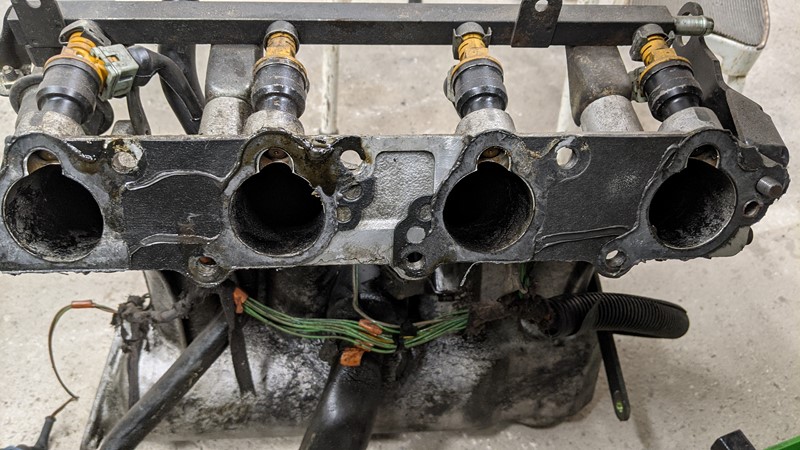

The air intake manifold isn’t meant to have any sealant on the connection to the engine. It looks very much like the fibre seals have been reused. Then a huge amount of sealant has been bunged in to save on the few pounds for new seals.

What doesn’t show in the picture is that some of the applied sealant covers the port for the injector. One end of the intake manifold didn’t seem to sit flush, further throwing out the fuel injection pattern! This could be worth one or two BHP, not a lot but the losses soon stack up.

The Timing Belt

During the engine strip, I had a look at the timing belt. It’s impossible to tell how long the timing belt has been on the car but the current belt is branded Pirelli, so not original. The date stamp isn’t legible, but that doesn’t always correlate to when it was fit. However, it is clear that this belt is past its best.

Of the 20 odd belts I’ve taken of Citroen engines in my automotive tinkering career, this is the most slack I’ve ever seen. And that is not a good thing for an MI16 engine. My normal test for tension is that it should be taught at 15° twist, I’ve never seen an installed belt on a running car twist by 110°.

Amazingly it gets worse. There is so little tension in the belt that the cam timing is out. This is the closest I could get the timing pin into the exhaust cam, with the intake cam fully pinned. It may not look like much, but it’s enough to lose a few more BHP. And the risk of a belt failure or timing slip is huge.

Missing nuts and bolts

Throughout the engine strip I noticed a lot of missing bolts. I guess some of these might have been ‘borrowed’ for other projects and engines, as the engine have been stored for a long time. Some are relatively minor, while some more significant.

Missing bolts on an old engine aren’t the biggest sin in the world. Only in some cases, they aren’t missing! They’ve been dropped into the engine and not recovered, pretty shoddy work that I find really annoying. In the case of the dropped intake manifold bolt below, it was replaced with a hex head bolt of way too much length.

In total, while stripping down the engine I found 8 spare fixings both metal and plastic. And while its great to get some of the original fixings back, there was a fantastic surprise to come.

The picture above shows the bolt that holds the fuel rail to the head. But more importantly, a 10mm socket! Now to anyone who’s worked on a car, this is very much the holy grail of car finds. Usually, 10mm sockets only go one way, so to find not one but TWO 10mm sockets lying on the engine!

Slack approach to repairs

One of the most worrying things I started to find during the engine strip, was metallic swarf. It wasn’t magnetic so I guess its aluminium. And it is absolutely everywhere, not just down the front of the block.

Rather worryingly there were some very long swirls of swarf down in the bottom of the cam belt housing. As if the lack of tension wasn’t enough of a risk to the engine on its own, swarf in with the timing belt isn’t going to do it any good. Eventually, I tracked this down to another bolt for the fuel rail which has been drilled out and retapped for a bigger size. Clearly, someone didn’t own a rag or a vacuum!

How bad is the engine after the strip?

Well despite the general filth and poor maintenance of the engine, it doesn’t seem to have particularly suffered. In fact, under all the grime, swarf and spare sockets is an engine that should be restorable to its former glory.

The plan for the car is to get it back on the road for less than the cars final value. This means the costs need to be controlled. Before I set about rebuilding the engine I need to understand where the 20 odd BHP are getting out. So next up will be some cylinder compression testing to see where the ponies are getting out.

M

NEXT – Cylinder head leak testing

PREV – Cleaning the Engine and Gearbox

Back to Citroen articles

Back to Automotive articles