When my great big blue tractor-shaped ‘dream come true’ arrived at my house back in September, it came with little by way of exterior lights. With all the lights wired back up, fluids checked, and big boy pants primed, it was finally time to take it for a first drive. Let me tell you how it went!

Tractors on the road

Throughout my driving career, I’ve had the opportunity to drive quite a few vehicles, including a splattering of tractors. Perhaps not surprisingly, the ‘dream come true’ Ford 7610 isn’t the first Ford tractor I’ve driven. As mentioned in a previous story, I annually rode in a 7610 in the early 90s and regularly drove a couple of hundred series tractors in the mid-00s. Namely a 3300 with loader and a 6600. The Ford 7610 feels very familiar, but I’m not quite working the controls instinctively yet.

That said, despite all the tractor hours I’ve had, I have never driven a tractor on the road in running traffic. Sure I’ve gone from farm to field on a backtrack in the middle of nowhere, but never on a real road with cars around. I am getting on in years, with a reasonably developed driving experience in all manner of big lumbering vehicles. However, getting the Ford 7610 tractor five miles down the road to the farm filled me with a little trepidation.

Back roads or bypass

Perhaps first and foremost in my list of negative outcomes was wing mirrors. I knew my Ford 7610 had a flat spot in the steering, so I perceived it wouldn’t have taken much to clip a parked or passing car. And at fifteen miles an hour or so, there would be many passing cars. I had a couple of possible routes, but ultimately it came down to a long winding route down back roads or down the much faster bypass.

Travelling at around one-quarter the speed of the rest of the traffic will always cause an increased risk of a collision. But, be it from distracted drivers or simply a lack of forward-thinking from other vehicles, the bypass had a whole separate set of risks. In the end, I opted for the bypass. Less likely to clip another car, space for other vehicles to pass, and an easier route.

And in the end, I need not have worried about the drive on the bypass whatsoever. The tractor is certainly not as big as it seems, sitting quite nicely in the wide lanes. I’ve definitely driven wider vehicles. With a low speed, there was plenty of time to respond to any changes. And with the Freelander and its illuminated lightbar following, there was no issue with other traffic.

My first drive but no top speed

Above all else, my first road drive in the tractor was enjoyable. Like a massive child on Christmas day playing with a new toy for the first time, I was wall-to-wall smiles. The trouble-free drive on the open road (well, I saw no traffic) was quite relaxing and therapeutic. And that is probably because the five-mile drive took around 55 minutes, which is an average of 11 miles per hour. Okay, that was with a short break, but the Freelander saw no more than 15 miles per hour on the whole journey.

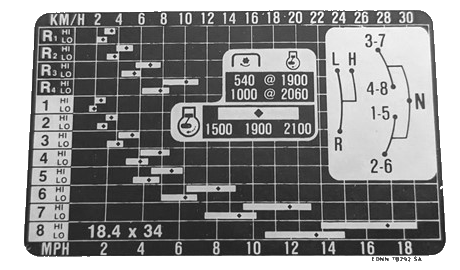

The reason became quite apparent a few days after the drive when flicking through the operator’s manual once again. My 1984 Ford 7610 has what is officially called an ‘H’ pattern gearbox. Fortunately not the much-maligned ‘Rubiks Cube’ gear selector. The ‘H’ pattern gearbox is mounted to the steering column with one selector for high/low and reverse and one for the gears. There should be a nice sticker on the dash, like in the picture above, to guide the operator in selecting the correct gear.

On my Ford 7610 with nearly 8000 hrs, the gear selection sticker is somewhat worn out in all the important places. This vague instruction diagram meant that I completed the journey in 8 LO, around 14mph and not 8 HI. An extra four miles per hour might not sound like much, but that’s nearly 30% faster! Another lesson learned.

The gap in the steering

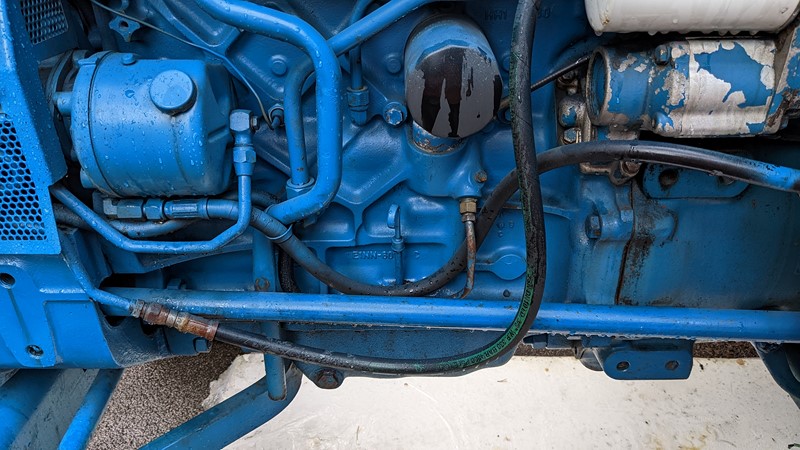

That steering play that I had been so concerned about was a bit of a mixed blessing. The power steering was a bit all over the place at very low manoeuvring speeds. So when manoeuvring on the drive, steering contributions from the pump would come and go, and I found it generally a little lazy. But the assistance was pretty constant once the tractor was on the road and moving. Clearly, the steering system needed some maintenance. However, it worked well enough, and after checking over all the steering links, there was nothing obviously amiss.

The play in the steering wasn’t too much of a worry at low speeds getting to the bypass. However, the dead spot became more apparent as the speed climbed. Speed, who am I kidding, I can run faster than most of the journey, and I’m not built for running. Once the tractor ran in a straight line, it would stay pointing dead ahead quite happily. The Ford maintained a level heading even over the odd divet or pothole in the tarmac. However, once a bit of steering input was needed, it was somewhat equivalent to piloting a boat. There was quite a delay between input and reaction, resulting in quite a bit of input being required to get it back into a straight line. Clearly, this was something to be looked into.

Home Sweet Home

After what felt like a very long day, we arrived at the farm with the tractor just before 11 am. A mixture of relief and fatigue made me rather happy to finally arrive. However, it was a very successful first drive. Nothing broke, and no significant amount of fluid appeared to have been lost. Temperatures seemed to behave, and the cabin was surprisingly comfortable. Although maybe trying to compare it to the TEA20 Fergie is a little unreasonable.

Now that I’ve completed my first drive of the tractor, and what a great one it was, I’m more confident in moving forward with general maintenance. There is nothing worse than getting a new project and finding it needs a lot more work than realised. Although there are a handful of minor things to take care of, like the spring setting for the seat or the out-of-place Sony XPlod radio, the mechanicals must be looked into first.

Servicing the important bits

Top of the list is to get the tractor serviced, including new oils and filters for both the engine and hydraulics. I also want to get the steering looked at by someone who knows the tractors. While I’m sure that I could poke about and eventually make things better, getting a professional in seems like good money.

Fortune would have it that I got talking to a local tractor engineering company at the Cheshire Ploughing Competition in August. I think, if anything, they were positively excited about getting their hands on something a little more vintage than their usual day-to-day stock. It was great to have a natter with someone knowledgable about the common faults, from a service and repair side.

My 7610 is already booked in for some work. And that is a story I will tell in the next article.

M

NEXT – Minor Service Turns Major

PREV – Ford 7610 – Wiring in the lights