After the first road drive in the 7610 back in September 2022, it became apparent the steering wasn’t entirely as it should be! While the play in the steering wasn’t immediately apparent on the drive, with a bit of speed built up, there was clearly a bit of play somewhere. Rather than lose a few months of trying to figure out the route cause, I decided to take the tractor to a local agri-engineering company, get them to do a service and look at the steering. The minor task of service turns major pretty quickly!

Cheshire Farm Machinery

Back in August, at the annual Cheshire Ploughing Match, I chatted with Andy from Cheshire Farm Machinery (CFM). While I’ve known about CFM for a long time, this was my first real engagement with the company. Andy was more than happy to chat with me about the 10 series, common faults and what CFM could do to help me with tractor maintenance.

In late October, I had my Ford 7610 booked in for a service at CFM and a look at the steering issues. The drive over on the back roads of Cheshire was far more enjoyable than the trip down the dual carriageway and uneventful. With the tractor dropped off, I headed home to await the news.

Servicing the tractor

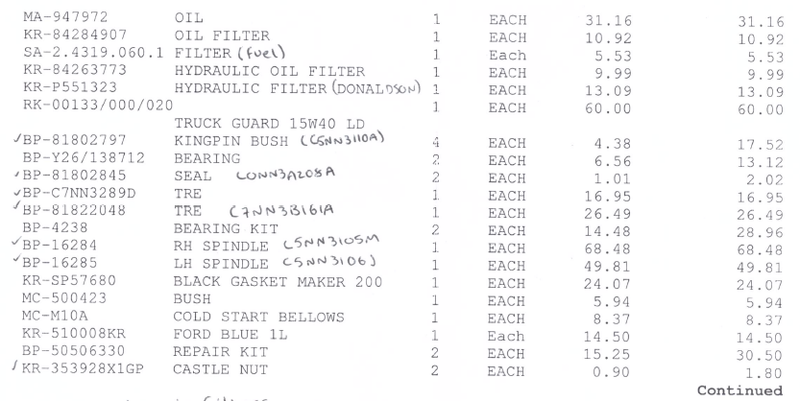

Given the complexity of modern tractors, I suspect that carrying out the service on this simple 1984 tractor was a pretty nice change for the technicians. Engine oil and filter, fuel filter, hydraulic filter and steering pump filter were all changed.

Clearly, someone was paying attention to the installation of the filters as well, with the fuel filter being installed with the text facing out. The fuel pump oil was also changed out, mainly having been replaced with diesel. Apparently, this is common and needs to be checked periodically.

There’s not a lot to show following the service. However, from the verbal feedback from CFM, it seems like the servicing side was pretty straightforward, and the tractor was given a full bill of health. Well, as good as a 7500-mile and 38-year-old tractor can be!

The Steering Issues

While the service was generally straightforward, the steering issues were a little more tricky to resolve. When I dropped the tractor off, the guys at CFM had a look at the steering spindles and could see an amount of play. So when they set out the find the steering issues, this was the first place they looked.

The spindle is shown in green in the image above. It should be wider at the top and bottom of the vertical shaft to provide bearing surfaces. These areas were so worn on the 7610’s spindles the middle section of the post was the widest point. That’s a tremendous amount of wear and clearly the route of my steering woes. The fix is simple but not cheap.

If they can be found, genuine replacement spindles cost around three to four times the cost of the £50 Sparex aftermarket replacement parts. However, the repair cost isn’t in the parts but in labour, as I was about to find out!

I like the lengths CFM has gone to do the job just right. They understand that while my 7610 is a light-use tractor, it will also get to some local machinery shows. To this extent, they took the time to repaint any disturbed areas. While I could have tackled this myself, it’s reassuring that they have taken this much care.

How major did the minor service become?

And how major did the service become? Well, it turned into a two-page invoice with a much longer list of parts than I might have expected. Spindles, track rod ends, bearings, paint. It’s a long, long list. That said, the cost of the parts isn’t too awful.

The real cost of the minor service turned major is in labour. The tractor spent nearly four weeks at CFM, and they slowly chipped away at the jobs. The invoice doesn’t break down all the hours, but more than 60% of the bill is labour alone. I think I may have done the job within a year with enough weekends. However, to have someone who knows what they’re doing complete the work quickly is priceless for me.

Taking the tractor back home

Between the spindles and the steering pump filter, the drive back from Cheshire Farm Machinery was a completely different experience from my first drive. With the work complete, the steering is more responsive, and the flat spot is nearly gone. I’m much happier driving the 7610 on the road now. I also noticed the front wheels sit at a considerably different angle from how they started. Something to keep an eye on over the next few thousand hours.

More work to do and parts to find

While the tractor only went in for a service, it returned much happier. The engine and hydraulics are serviced and notably improved. The steering issues are now as resolved as they can be. While the minor service turned major, and the cost was high, it was worth it.

With a clean bill of health, I can see a busy future ahead for this Ford 7610. Fortunately, there are plenty of jobs around the farm, especially if I can find a loader.

Unfortunately, there are still many parts to find to get the tractor back to top form. The lack of an adjuster on the lift arms is already an issue in levelling the flail mower. This could take a good bit of searching to find the missing parts!

I’ll also have to do something about the damage to the cab roof. The clamshell has evidently been opened without taking out the rear bolts. So instead of the upper and lower parts of the roof hinging open, the fibreglass lip at the rear of the roof has been shattered. Doh!

Until Next time, keep tractoring!

M

NEXT – Ford 7610 – Fitting a Loader

PREV – Ford 7610 – First Drive

Pingback: Ford 7610 - Fitting a loader - BX Project